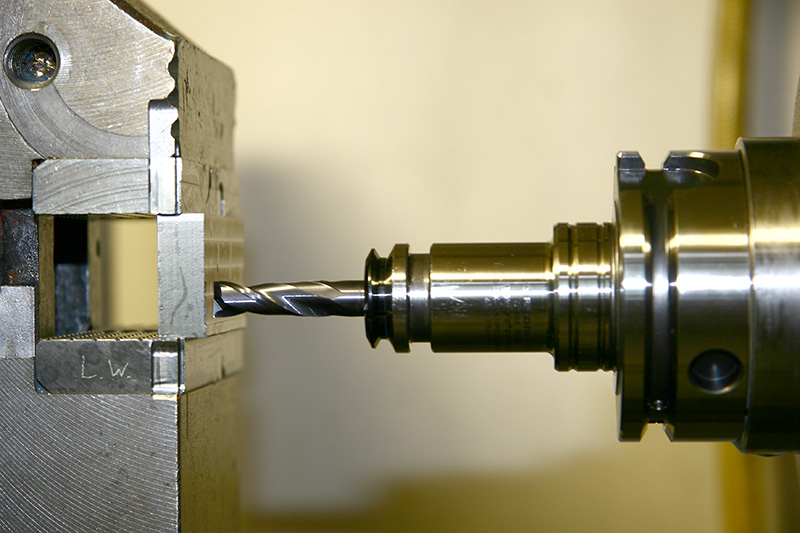

Characterization of Regrinded Cutting Tools

To what extent does the cutting tool performance decrease within the tool life cycle when milling nickel-based alloys?

Challenge and Motivation

- Extensive tool wear in machining of new and advanced nickel-based alloys leads to high tool costs

- The tools are regrinded several times to reduce tool costs

- With several regrinding operations, a loss of performance of the cutting tools can be observed

Objectives

- Evaluation of a possible performance loss of cutting tools in milling Inconel® 718 due to several regrinding operations

- Identification of possible causes for performance loss

ICTM Aachen – International Center for Turbomachinery Manufacturing

ICTM Aachen – International Center for Turbomachinery Manufacturing