In-situ Part Quality Improvement by Adaptive Laser Control (cw +pw) in LPBF

How can the as-built part quality be improved with minimum deterioration of process productivity by adaptive laser control?

Challenge and Motivation

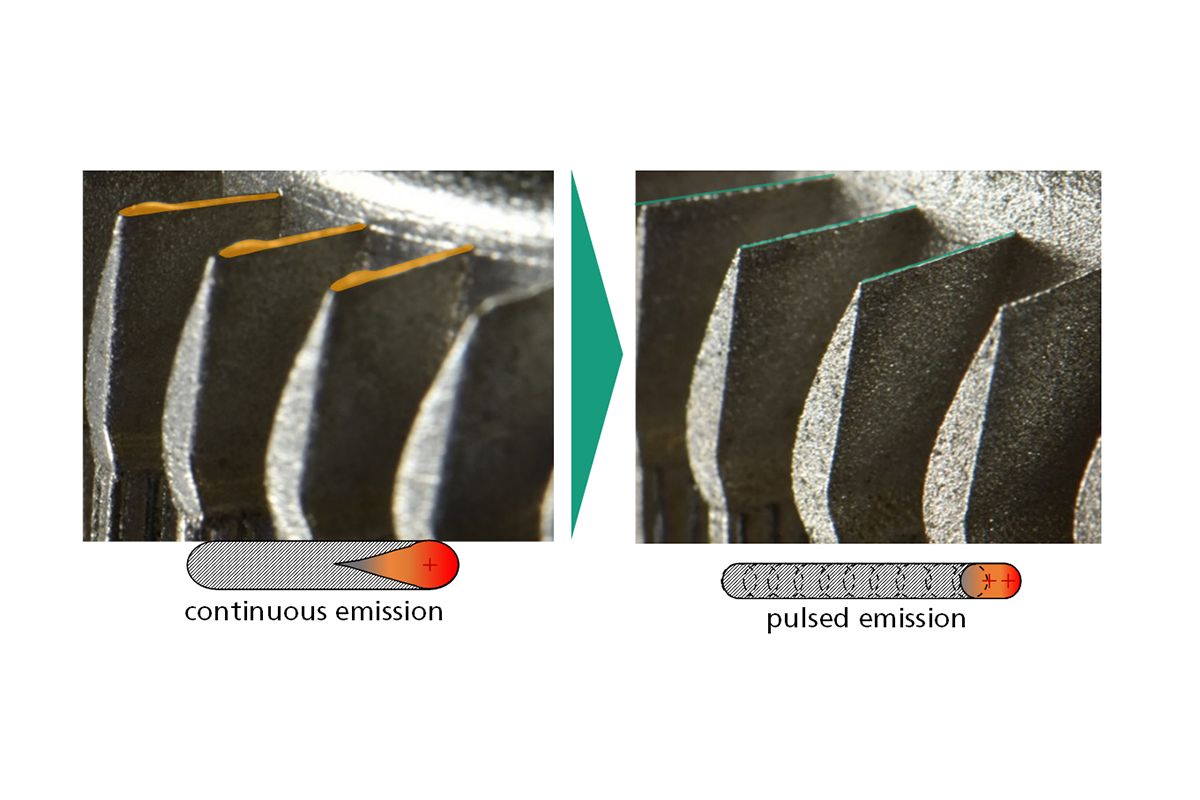

- Use of continuous (cw) contour exposure leads to sintered powder (surface roughness) and heat hotspots at filigree structures (geometric deviation) leading to increased need for subtractive post-processing

- Pulsed (pw) contour exposure expected to improve surface roughness and geometric accuracy, but lacks productivity compared to cw exposure

Objective

- Transfer of pw processing strategy to higher layer thickness(es)

- Comparison of build part surface properties to state of the art

ICTM Aachen – International Center for Turbomachinery Manufacturing

ICTM Aachen – International Center for Turbomachinery Manufacturing