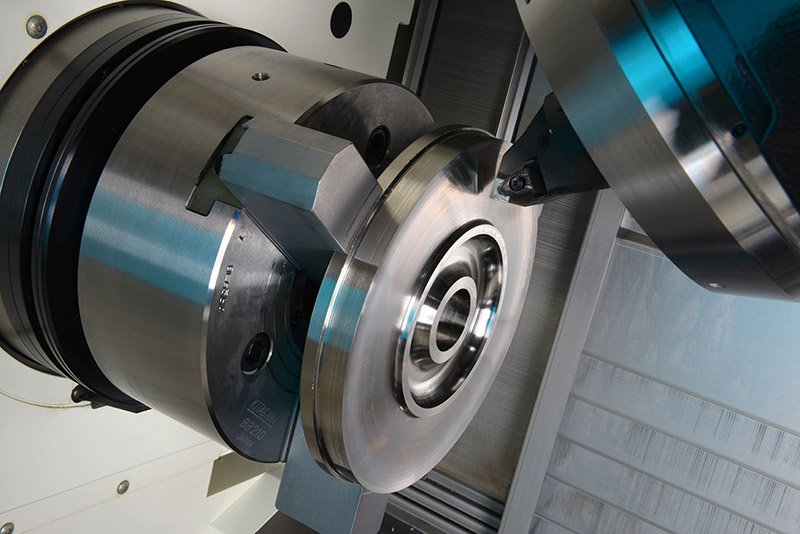

B-axis turning to avoid machining steps and tool changes

What are the advantages and challenges in B-axis turning of engine disks?

Challenge and Motivation

- In most cases, turning is carried out with a one-tool orientation.

- This requires a wide variety of different turning tools to manufacture the final component geometry as well as setting the tool down on the component contour.

- Furthermore, tool wear only occurs in a small area of the cutting insert.

Objective

- Moving the B-axis during turning has various advantages.

- On the one hand, machine points can be avoided and the variety of tools can be reduced.

- On the other hand, the tool wear can be distributed over the cutting insert.

ICTM Aachen – International Center for Turbomachinery Manufacturing

ICTM Aachen – International Center for Turbomachinery Manufacturing